Chelsea Artisans and Fusion Glass have just completed manufacturing 300m2 of kiln formed laminated glass wall panels for the prestigious new Mandarin Oriental Hotel in Doha, Qatar. The panels are being used to form partitions between lift lobbies and an open lift atrium allowing light and form to permeate through the building in keeping with the design intent of Architects John McAslan and Partners and Interior Designers David Collins Studio.

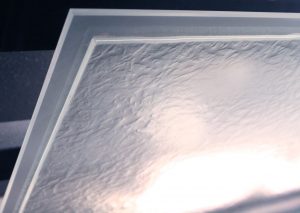

Each kiln formed laminated glass wall panel comprises a 10mm low iron toughened kiln formed glass front face resin laminated to a 6mm low iron toughened rear face; the back of the panels receive a flat tone sandblast to provide opacity. The panels were pre-drilled to receive fixings for incorporation into the steel framework of the atrium.

The largest panels are 1740 x 3165mm and weigh approximately 220kg. The kiln formed panels are manufactured in Chelsea Artisans’ gas fired kilns at their manufacturing premises in Croydon, south London. These are the largest ovens currently being used for kiln forming glass in the UK allowing for a theoretical maximum size of 7.00 x 4.00m.

Through Fusion Glass Designs the company has pioneered kiln forming of glass on a commercial scale. A range of standard patterns and designs are available, but it is also possible to develop bespoke patterns and shapes and to create individual pieces of artwork.

You must be logged in to leave a reply.