Description

Product Details

SPECIFICATION:

Available in annealed or toughened (tempered) glass to comply with BS EN 12600, BS 6206 Class A or required national safety standard.

MAX. PANEL SIZE:

THICKNESS:

4mm+4mm (nominal overall thickness 10mm)

6mm+6mm (nominal overall thickness 14mm)

Also available in a combination of other glass thicknesses.

GLASS OPTIONS:

Low Iron (crystal clear) - as standard

Float Glass (slight green tint)

Mirror Backed

EDGE OPTIONS:

Polished all round (PAR)

Arrised all round (AAR)

Ground all round (GAR)

SURFACE FINISHES:

Clear (standard) or sandblast.

APPLIED FINISHES:

Opaque colours, transparent colours or mirror finish can be applied to the rear leaf of the glass.

PROCESSING OPTIONS:

Shaping, drilled holes, notches, waterjet cutouts.

TOLERANCES:

+/- 2mm (glass size)

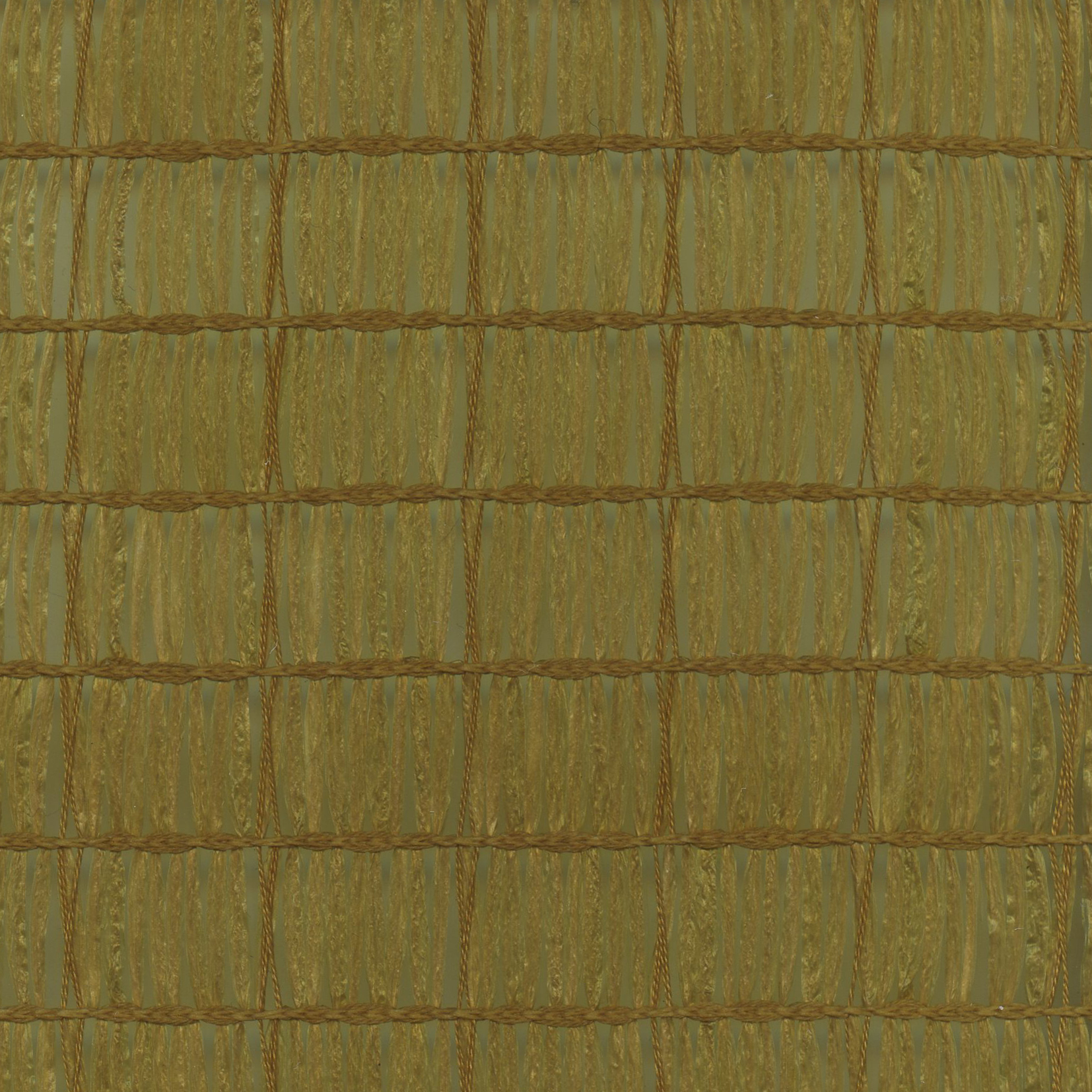

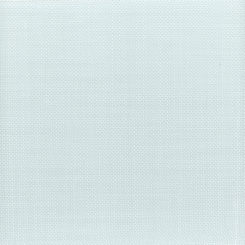

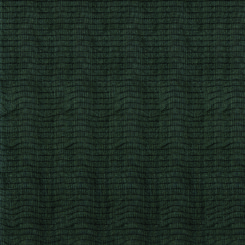

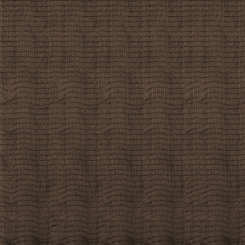

COLOURS:

Please see Fabric Laminate Guide for options.

QUALITY & FINISH:

Fabrics are woven products and by their nature may have slight variations or irregularities in the weave depending on fabric type. Every attempt will be made during the laminating process to minimize the visual impact of such imperfections and maintain a consistent and even distribution, but it is not possible to guarantee they will be eliminated.

PLEASE NOTE:

When specifying this product please ensure that the end user is aware of material limitations as Chelsea Artisans cannot accept rejection on this basis as per our T&Cs.

Some directional variations may occur between panels. On large or complex projects we recommend prototype panels are produced for sign off and final approval.

A mirrored or opaque backing layer of glass will need to be combined with the fabric when product is used as cladding or fixed back to a structural substrate.

Fabric laminate products are not recommended for use in external or wet/damp environments unless fully framed and sealed. We advise that particular care must be taken to protect the edges of laminated panels against water ingress. Prolonged contact with water can cause the interlayers used in laminating to deteriorate, both in appearance and adhesion. Edges should also be protected from contact with compounds and products containing mineral or vegetable oils and unsuitable glazing compounds such as acid curing silicones.

For more information please refer to our Advice Manual (available on request).